Backlash

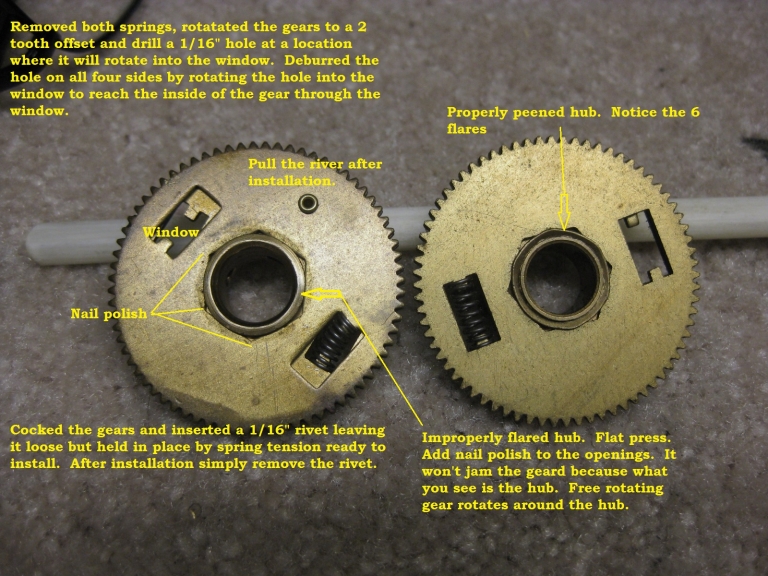

Note: Only one spring installed so the window can be seen with two spring holding nipples in view.

When drilling the hole for the rivet or screw make sure it is the same distance from the axle so it can be seen through the window. This will enable you to deburr the hole from both sides to keep it from binding.

Note the gear on the right is peened in six spots. This will hold the gear on the capacitor shaft properly. The gear behind is floating and spring loaded to prevent backlash.

The gear on the left is slightly loose because of the incorrect peening process and causes erratic frequency positioning and backlash.

When installing this gear, wind the gears two teeth. Be very careful to wing in the correct direction or the springs will likely disappear in the shack somewhere. When winding in the wrong direction the springs will launch almost immediately. Note the two spring holding nipples in window of the top left photo. Wound the wrong way, one nipple vanishes behind the gear releasing the spring.

Test for backlash and if you detect any, clean the VFO cap bearing and lube with clock oil, not grease.