Service Note 012C

THE SR-2000/SR400/SR400A/HA20 VFO ------- Drift and stability

Drift:

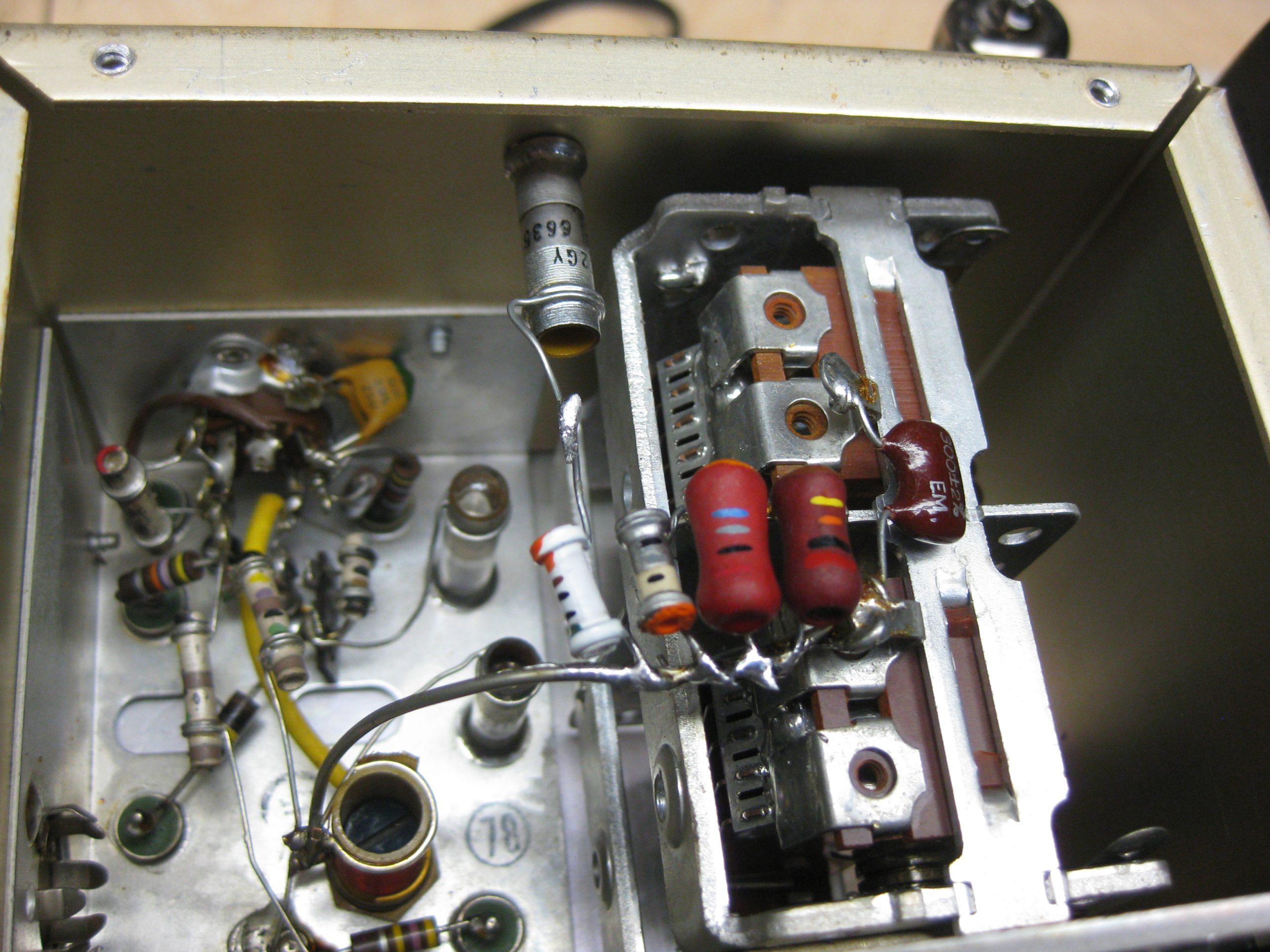

The primary cause of excessive drift and abrupt frequency change is almost universally attributable to the three temperature compensating Dog Bone capacitors at the top of the VFO, C121, C123, and C124; two 39pf n150 and a 47pf n30. Dog Bone capacitors were used until very late in the SR-400A production cycles and changed to class 1 disc ceramic caps. The SR-2000 was the first of the SR-2000/400/400A group manufactured, followed by the SR-400 then SR-400A. You will normally find the disc ceramic caps in the very late radios only. The Dog bone caps were changed to ceramic disc caps because they became unavailable from their vendor.

Over time, the clear coat on C123 and C124, the 39pf N150 Dog Bone version tends to lift and peal causing the VFO to suddenly shift a few, to hundreds of cycles. Also, they begin to drift as the temperature compensation attributes begin to change: this malady seems to be limited to the 39pf caps only. So change the caps you say! Well the vendors either don’t have them or want to sell 10,000 or none and we are left to our own devices. There is a solution --- go to Surplus Sales of Nebraska and check their caps: they are the only source that I am aware. You won’t find 39pf N150 or 47pf N30 caps but you can do some simple math to solve the problem. Simply multiply the capacity 39pf (39) times the N150 (150) to obtain what we will call the temp product and do the same for the 47pf N30 cap. (39 X 150 = 5850 X 2 = -11700) + (47 X 30 = -1410) = -13110. Use any combination of capacitors to total 125pf multiplied by their respective N values to equal 13110 and you are home. I have used a 39pf N80 and 39pf N220 for that combination as well as a 68pf N150 and 10pf N150 for the two 39pf caps. I have not once replaced any other caps in the VFO for failure.

One other attribute regarding the temperature compensating caps; they are manufactured in a variety of reaction times. The capacitors in the Hallicrafters VFO are somewhere in the center whereas I believe the Collins 75S3 fall in the rapid category. The point here is a particular VFO mechanical/heat configuration may require one or the other. In the Hallicrafters VFO, they must present medium reaction time or rapid drift swings will occur during warm up.

The temperature compensating capacitors used in this VFO are strategically placed to compensate for heat variations. There are two (39pf N150) and a (47pf N30) at the top of the VFO near the tuning capacitor. The tuning capacitor has a combined total range of 48pf, (20pf to 68pf) with a P55 positive temperature coefficient. There is an (82pf N80) capacitor at the bottom on the tube socket near the V100 varactor diode. The varactor diode is variable from 40pf to 240pf but is in series with a pair of 47pf npo capacitors reducing its swing significantly. The V100 varicap is not a drift problem because the cumulative capacity varies insignificantly with heat. The main tuning capacitor however does vary 48pf from end to end. If it's at the low end, 20pf, with a P55 positive temperature coefficient, the capacitive drift quotient will be 20X55=+1100 and if the capacitor is at the high end it will have a 68X55=+3740 drift quotient. What does that mean to you?

Hallicrafters QC used 5% components in the VFO. Their specifications state that after a 15 minute warm up, the first hour could drift 250 cycles and less than 100 cycles after that. This commitment was met.

All capacitively tuned VFO's will drift differently throughout the tuning range and most inductively tuned VFO's will do so as well. Both Hallicrafters and Collins boast less that 100 cycles of drift after warm up for the SR-2000 and 75S3B. With the drift mitigation change the SR-2000 will have an approximately 100Kc range in the center of the 500Kc VFO spread where drift will not exceed 10 cycles per hour. More than adequate to support any application. The band ends will see less than approximately 50 cycles of drift.

The SR-2000/SR-400/SR-400A, and HA-20 use the same VFO. The only variation is the HA-20 has the 12BA6 mounted on the back of the VFO; the others on the left side. You will find this CTO to be one of the highest performing VFO's from that era.

The VFO can be modified to accomplish the enhanced drift objectives using the drift mitigation change; that is if you have a lot of time in your schedule.

Is the 100 cycle per hour standard specification acceptable? Absolutely, because you could tune a QSO today and come back from vacation and it will be as you left it because drift after warm up is generally a wandering few cycles back and forth or stable, not unidirectional. The effect of a 100 cycle variation on a sideband signal will be difficult to hear and if it can be heard, a feather light tweak will correct it and after warm up it will cease.

If drift becomes annoying do the following to determine whether there is a problem.

Tune to the bottom of the band and measure the frequency of the VFO. Measure the drift every minute for the first 15 minutes, every 15 minutes for the next hour, and at the end of the next hour. Do the same for the center of the range and top end of the range. If the VFO is one of those that fell into the perfect category, you will see very little drift in the center measurement, a downward drift in the high end, and an upward drift in the low end measurement. An imperfectly temperature compensated VFO will have the low drift area somewhere other than the center. All CTO's display this behavior. It is natural because the tuning capacitor has a positive temperature attribute and when you vary the capacity the positive TC varies equally. A properly designed and adjusted CTO will be TC stabilized in the center of the tuning range. Also note that you will find the tuning capacitors in quality VFO's to be universally very wide spaced to reduce increasing capacity with heat.

NOTE: The drift caused by varying the capacity of the tuning cap can be mitigated with a series capacitor with a negative temperature coefficient. This is a project for someone who is incredibly fussy and has an infinite amount of time to dispose of. The attainable drift parameters published by Hallicrafters and drift mitigation changes render any further efforts without merit.

Kindest regards and hope you find this useful and interesting --- Jim K9AXN Copyright 2011

More to follow: